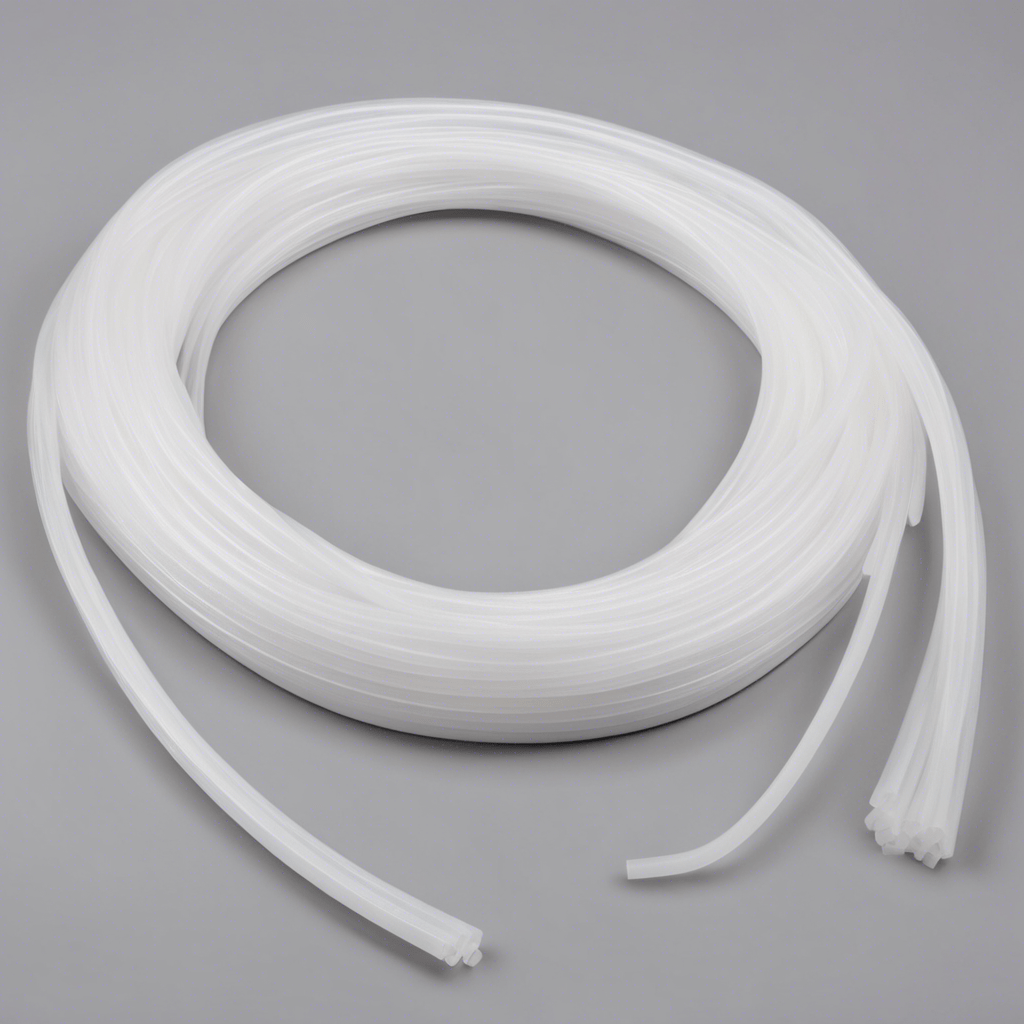

Process Valve and Instruments supplies top-notch tubes from Birmingham, AL, to any place in the United States through LTL or ground delivery. With 38 years of experience (since 1986) as a major tube supplier, our extensive product range includes different types of industrial tubes for any purposes you need.

We supply quality, state-of-the-art imported or domestic tubes from the best manufacturers to ensure high-standard products and customer satisfaction.

So, you are one phone call (800-749-8068) away from accessing the best tubes for automotive, medical, aerospace, and any other industry or application. You can even fill out the form below and we’ll call you to discuss your tube needs.

Read on to learn more about our wide range of tubing products.